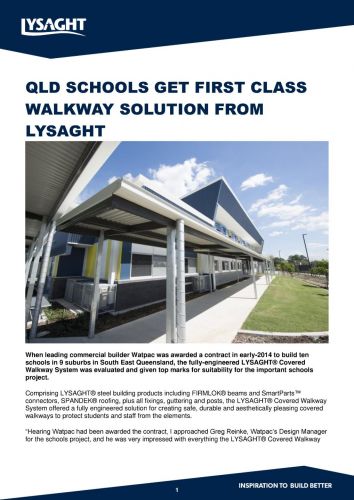

When leading commercial builder Watpac was awarded a contract in early-2014 to build ten schools in 9 suburbs in South East Queensland, the fully-engineered LYSAGHT® Covered Walkway System was evaluated and given top marks for suitability for the important schools project.

Comprising LYSAGHT® steel building products including FIRMLOK® beams and SmartParts™ connectors, SPANDEK® roofing, plus all fixings, guttering and posts, the LYSAGHT® Covered Walkway System offered a fully engineered solution for creating safe, durable and aesthetically pleasing covered walkways to protect students and staff from the elements.

“Hearing Watpac had been awarded the contract, I approached Greg Reinke, Watpac’s Design Manager for the schools project, and he was very impressed with everything the LYSAGHT® Covered Walkway System offered - particularly the fact that it’s fully engineered,” Chris Hooper, Lysaght’s QLD/NT Segment Manager - Infrastructure, explained.

“Additionally, it’s a quality system that features FIRMLOK® beams, SPANDEK® roofing and guttering all made from 100% Australian-made COLORBOND® steel; it has a 20 year Lysaght structural warranty, a 15-year BlueScope perforation warranty and comes with Form 15 Compliance Certification.”

At Watpac’s request, Chris Hooper and the Lysaght team then built a 15m display covered walkway at Lysaght’s Archerfield site in Brisbane for Watpac, their client Plenary Group, Plenary Group’s client, the Queensland Government Department of Education, Training and Employment (DETE), and project architects GSA Architects to inspect closely.

“There were many factors that made the LYSAGHT® Covered Walkway System ideal for the schools project,” Greg Reinke, Watpac’s Design Manager - QLD Schools Project Administration, stated.

“The LYSAGHT® Covered Walkway System was deemed a much better fit aesthetically, with high gloss COLORBOND® beams compared to welded hot dipped galvanised beams.

“The difference in terms of lead times and logistics was also a key factor,” Greg Reinke continued. “With a hot dipped galvanised structure any adjustments on site can compromise the hot dip galvanising, requiring members to be sent back to be recoated.

“With the LYSAGHT® Covered Walkway System we had a component-type product that had the flexibility to more easily integrate with existing structures and more readily allow for any changes if required; this was extremely important as walkways are one of the last elements and are quite critical time wise in closing out a project.

“Underpinning the many product benefits were the quite substantial warranties that come with the system and the reputation for quality with Lysaght, which certainly helped get them over the line.”

Given the green light, the Lysaght team utilised Lysaght’s CC Builder Software to design approximately 1,800sqm of covered walkways for Stage 1 of Burpengary Secondary School and Pimpama Primary School, consulting closely with Watpac and GSA Architects to deliver the final designs.“

There were many factors to consider, particularly in terms of safety,” Chris Hooper explained. “The structures had to be trafficable, so extra internal beams were required, and location of posts was carefully considered, particularly at busy walkway junctions and where walkways adjoined school structures.”

Lysaght assisted Watpac in the selection of RHM Building Innovations to build the Pimpama and Burpengary schools’ Stage 1 covered walkways which were completed over a three month period from September to November 2014.

Construction has now commenced on Stage 1 of Griffin, Caboolture West, Ripley Valley and Pallara schools, with LYSAGHT® Covered Walkway System product due for installation from May through to September 2015, with Bellbird Park, Redbank Plains and Springfield schools to follow in 2016.