THE PROJECT

There’s a growing trend in the design and construction of public buildings to specify steel cladding for the considerable benefits it brings to the structure. Steel’s visual appeal, low maintenance qualities, ease of installation and warranty advantages, all make it an increasingly popular choice.

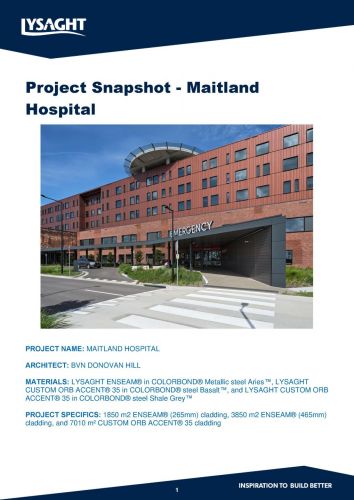

Case in point being the new Maitland Hospital at Metford which opened it's doors to patients in early 2022. The project has seen a range of LYSAGHT® steel building products being utilised to great effect, under the direction of award-winning architectural firm, BVN Donovan Hill.

The Metford build will significantly add to the health services available to residents of the growing Maitland and Hunter communities, and will achieve this purpose with visual flair by introducing a range of colour palettes, materials and installation techniques to deliver architectural intent. Included in this vision was to create sections of the building’s façade to replicate the look of a barcode, characterised by bold vertical lines of various thickness.

Aesthetics aside and in keeping with government requirements relating to longevity and maintenance, the cladding also provides the material durability that’s required in such projects.

THE SOLUTION

Lysaght Business Development Manager, Will Pereyra, said that the breadth of Lysaght’s product portfolio including an extensive colour palette, gave architects BVN Donovan Hill extensive design scope.

“We supplied a combination of ENSEAM® cladding at widths of 265mm and 465mm as well as the deeply corrugated CUSTOM ORB ACCENT® 35 cladding in COLORBOND® steel colours Basalt™ and Shale Grey™ for two elevations,” Will said.

“CUSTOM ORB ACCENT® 35 features 35mm ridges which helps to create deeper shadows – it’s ideal for the scale of this building. A shallower profile was originally specified but would not have achieved the desired shadow line and impact.

“The use of ENSEAM® cladding at two different widths continues the barcode effect. Given the length of the cladding which was applied from floor to ceiling, we opted to use 0.7mm thickness. At this thickness the material has the extra structural stability to withstand the thermal expansion and contraction that occurs as the sun moves over the structure.”

Will said that Lysaght also worked closely with the architect and client to ensure that the preferred cladding colours were achieved, particularly with LYSAGHT ENSEAM® in COLORBOND® steel Aries™.

“We were able to secure a custom-width coil of COLORBOND® Metallic steel Aries™ that would allow both the ENSEAM® cladding and the required flashings to be rolled from a single coil, in order to minimise waste and keep costs down.”

Ensuring the fit-for-task suitability of LYSAGHT® building products on the project, Lysaght was heavily involved in the product’s technical certification process to ensure that they met fire and water-resistance requirements to Australian Standards, this included the design of flashings.

THE PROCESS

Taking care of the cladding installation on the Maitland Hospital project was ABS Facades, a company with considerable experience in fitting steel cladding products. Yet despite this experience, Lysaght was still involved during the installation phases with regular site visits to assist with any technical queries and to inspect the work as it progressed.

“We think it’s important to continue our support beyond specifying the products and managing the certification process – the correct installation of the various LYSAGHT® steel building products is another focal point to ensure that the range delivers on its promised longevity, low maintenance qualities and visual appeal,” Will said.

“Prior to each level of the build being completed, our team members – in particular Lysaght Key Account Manager, Michael Gairns – were on site reviewing installation of the cladding and signing off on the work before scaffolding was removed.

“The end result has definitely been worth the extra effort,” Will said.